High-Performance Metal-Core Catalytic Converters: Revolutionizing Gasoline Vehicle Emissions Control

Introduction

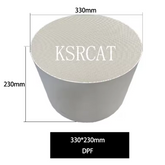

In the era of stringent environmental regulations and growing eco-consciousness, high-performance catalytic converters with metal cores have emerged as critical components for gasoline vehicle exhaust systems. The product showcased at ksrcat.com (200-100 cells, 114x104mm) exemplifies cutting-edge technology designed to maximize emission reduction while ensuring durability and cost-efficiency. This article delves into the science, applications, and advantages of these advanced converters, providing actionable insights for automotive engineers, environmentalists, and aftermarket buyers.

1. What Is a Catalytic Converter?

A catalytic converter is a compact reaction chamber integrated into a vehicle’s exhaust system. It contains catalysts (typically platinum, rhodium, and palladium) that transform harmful pollutants—carbon monoxide (CO), unburnt hydrocarbons (HC), and nitrogen oxides (NOx)—into less toxic gases like carbon dioxide (CO₂), water (H₂O), and nitrogen (N₂) through oxidation and reduction reactions5.

Key Features of Metal-Core Converters:

200-100 Cell Density: Optimizes exhaust flow and catalytic surface area for higher efficiency.

Metal Substrate: Enhances thermal conductivity, durability, and resistance to vibration compared to ceramic cores.

114x104mm Dimensions: Compact design suitable for diverse vehicle configurations.

2. How Metal-Core Converters Work

2.1 Catalytic Reactions

Oxidation: Converts CO and HC into CO₂ and H₂O using platinum/palladium catalysts.

Reduction: Breaks down NOx into N₂ and O₂ via rhodium catalysts1.

2.2 Advantages of Metal Substrates

Faster Light-Off: Metals heat up quicker than ceramics, reducing cold-start emissions by up to 30%.

Durability: Withstands extreme temperatures (up to 1,000°C) and mechanical stress15.

Weight Reduction: Lighter than ceramic equivalents, improving fuel efficiency.

3. Applications in Gasoline Vehicles

3.1 OEM Integration

Automakers prioritize metal-core converters for:

High-Performance Engines: Superior heat dissipation prevents catalyst sintering.

Hybrid Vehicles: Compatibility with start-stop systems due to rapid thermal response.

3.2 Aftermarket Upgrades

Emission Compliance: Helps older vehicles meet Euro 6/EPA Tier 3 standards.

Performance Tuning: Reduced backpressure enhances horsepower without sacrificing cleanliness12.

4. Environmental and Economic Benefits

4.1 Emission Reduction

CO/HC Reduction: Up to 90% lower than non-catalytic systems1.

NOx Control: Critical for urban air quality improvement.

4.2 Cost-Effectiveness

Longevity: Metal cores last 100,000+ miles, reducing replacement frequency.

Recyclability: Precious metals (Pt, Pd, Rh) are recoverable, lowering lifecycle costs5.

5. Installation and Maintenance Tips

Positioning: Install close to the engine for optimal light-off performance.

Diagnostics: Use OBD-II scanners to monitor catalyst efficiency.

Avoid Contaminants: Leaded fuel or silicone-based sealants can poison catalysts.

6. Industry Trends and Future Outlook

Nanotechnology: Emerging catalysts (e.g., FeN₄ stabilized by Pt) promise higher durability4.

EV Transition: Converters remain vital for hybrid/plug-in vehicles during the shift to electrification6.

Conclusion

The ksrcat.com metal-core catalytic converter (200-100 cells, 114x104mm) represents a pinnacle of emission control technology, blending performance, compliance, and sustainability. As regulations tighten globally, adopting such innovations ensures both ecological responsibility and operational excellence.

Call to Action: Explore ksrcat.com’s product line to upgrade your vehicle’s exhaust system with confidence.

Leave a comment

All blog comments are checked prior to publishing